Alternative Fuel in

Ndabibi, Kenya

A collaboration with Arlum Back, Frank Huang, and Josphat Macharia of the Ndabibi Environmental Conservation Centre to explore the use of alternative fuel in Kenya.

During the spring semester of my junior year of college my class worked remotely via email and phone with Josphat Macharia of the Ndabibi Environmental Conservation Center to address a list of issues he and his community was experiencing. My team and I focused on the problems that arise when using charcoal or wood as fuel for cooking. In the summer of 2013 I traveled to Ndabibi to research this subject further along with my professors and six other students

14% of Kenya has access to grid electricity. Most families use kerosene lamps or candles for light, batteries for electronics and biomass fuel for cooking and heating. Exposure to the smoke that is created from burning biomass fuel such as wood, charcoal, or corn cobs causes chronic eye and lung diseases; killing approximately 1.6 million people a year. Deforestation is also a huge issue in Kenya, and as trees become more scarce, the prices of wood and charcoal increase, making it difficult for families to afford fuel. The illegal charcoal trade in Kenya provides many poor families with a steady source of income, exacerbating deforestation.

But theres hope! Meet Josphat, founder of the Ndabibi Environmental Conservation in Kenya. He educates the community about organic agriculture, water conservation and collection, alternative fuels, and various other sustainable practices. On his farm Josphat uses fuel by generating biogas from manure, burning paper briquettes, and burning charcoal and wood.

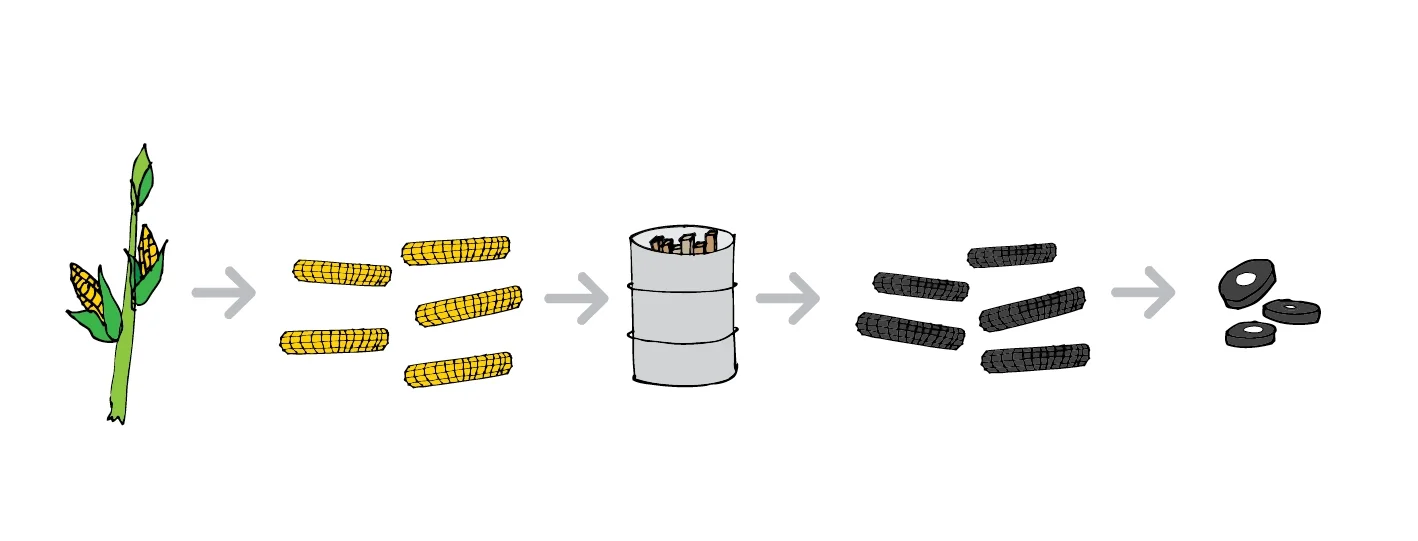

Charcoal from wood burns cleanly for a long time, however it is expensive, and it is a major contributor to deforestation. Paper briquettes are an alternative that Josphat has begun to employ on his farm because they make use of waste material, but they do not last nearly as long as charcoal and produce much more smoke. Briquettes made from Biochar are inexpensive, they make use of waste material, and they burn cleanly and longer than charcoal made from wood. For these reasons we became very interested in exploring the use of biochar briquettes, so we attempted to make our own. Josphat expressed that he has an abundance of corncobs and there is little use for them so they are frequently discarded onto the road. For our purposes however, corncobs proved to be ideal.

An old water heater that we found in a scrap yard turned out to be a perfect miniature charcoal making kiln. Minah, who works at the NECC with Josphat helped me punch holes in the bottom of the water heater. Josphat's daughter helped me load the kiln with dry leaves, sticks, and corncobs that he has been saving to use as fuel. Once the kiln was finished and cool we ground up the charcoal to use as powder.

Our biowaste briquettes were a little difficult to ignite, but once they got going they burnt clean and were efficient. Lasting for about 30 minutes they produced minimal smoke and became very hot. Even though the combustion isn’t as powerful as charcoal’s, our Biochar seemed to be a much better alternative because there are less harmful fumes.

Making Charcoal from Biowaste

Things you will need:

Three flat rocks bricks can also be used to lift the kiln off the ground

55 Gallon Steel Drum This is where the corn husks and other materials are burned to make charcoal

Large Stick This creates a chimney in the kiln

Corn Husks or other biowaste such as pine cones or sticks to be turned into charcoal

Long Dry Grass This creates a wic on the bottom of the kiln

Matches To set fire to the kiln

Large Bowl This is used to mix the charcoal powder and the binding material

Large Bag This is used to crush the charcoal in

Binding Material Ground Cassava or cornflour works well to mix with the charcoal powder to create strong briquettes

Process

Collect biowaste such as cornhusks, pine cones, twigs, etc.

Raise kiln off of the ground with sticks or stones so that air can flow through the kiln allowing the fire to burn evenly.

Create a wic with long grasses and stuff into a hole on the botton of the kiln.

Before filling the kiln with place a large stick in the center. This creates a hole that allows air to flow evenly throughout the kiln.

Light the wic at the bottom of the kiln.

Allow to burn for 10-15 minutes.

Lower the kiln from the sticks to the ground and place a lid on top to create an anaerobic environment.

Collect the charred biowaste.

Crush the biowaste into a relatively fine powder and mix with a binding material such as corn syrup.

Use a simple press to create dense briquettes.

Allow briquettes to dry in a sunny area.